Porcelain Insulator News

by Elton Gish, NIA #41

Reprinted from "Crown Jewels of the Wire", September 1990, page 15

Fred Locke, as many of you know, is considered the "father of porcelain

insulators". He developed the first high voltage porcelain insulators

during a time when transmission of electrical power was in its infancy. voltages

used in the transmission of power progressed rapidly from 10,000 to 60,000 volts

during the period from 1895 to 1903. This was Fred's heyday; the only period

which Fred was directly involved in the design, manufacture, and sale of

porcelain insulators. While he sold millions of porcelain insulators during that

time, only those made from late 1898 until 1903 were produced in his factory.

All of that production was of rather poor quality, no doubt the result of highly

competitive pricing, the rapid pace of power line construction, and ever

increasing line voltages.

Insulators made with an eave gutter and rain spout

were the first multipart insulators. They were designed by Fred Locke in early

1900 for use on the 40,000 to 60,000 volt Bay Counties Power Co. (a double

circuit 152 miles long from Colgate to Oakland) and Standard Electric Company

(219 miles long from Electra to Oakland and San Francisco) lines.

CLASSIC EAVE AND SPOUT AND SPOUT INSULATORS MANUFACTURED BY FRED

M. LOCKE

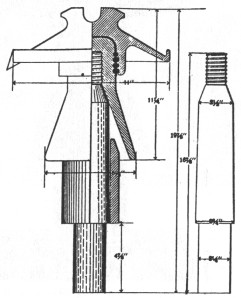

This is M-2795 as used on the Bay Counties and Standard Electric Companies

line in northern California from 1900 until 1904.

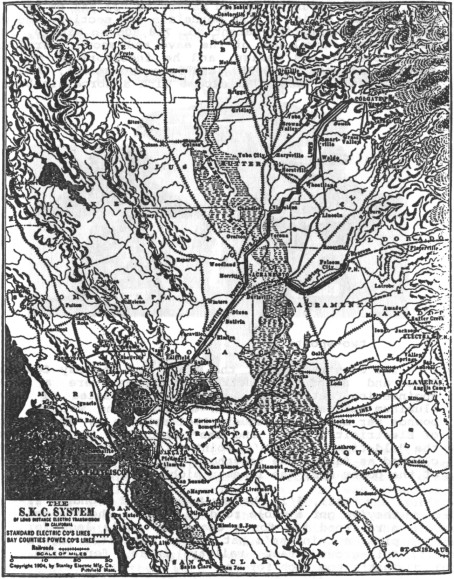

This map shows the routes of the power lines which used M-2795 as installed

by the Bay Counties and Standard Electric Companies (The Electrical Age dated

October, 1904).

Those two

systems covered 371 miles in northern California. Many tens of thousands of M-2795, which had a single

spout, were installed. This insulator used a glass base in combination with a

porcelain top. The purpose of the eave gutter and rain spout was to direct

rainwater away from the crossarm to prevent wetting of the underside of the

insulator. A mixture of sulfur and sand was used as cement.

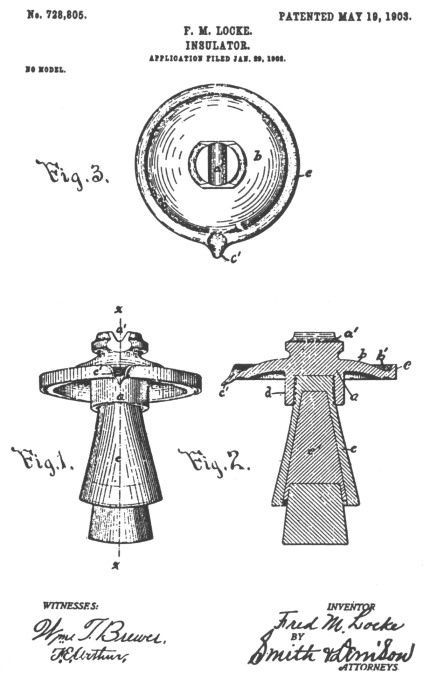

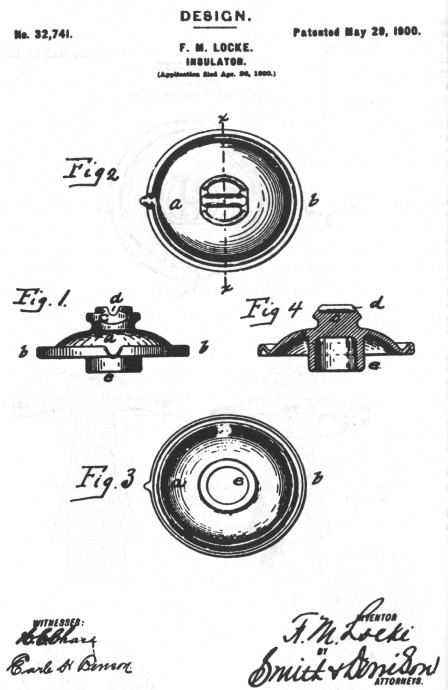

Fred was granted

design patent No. 32,741 on May 29, 1900 for the design of the porcelain top

section. He was later granted utility patent No. 728,805 on May 19, 1903

covering the novel use of the eave and spout. Fred was very proud of his design,

and he incorporated it into several styles: M-2335 (the rare two-spout), M-2795,

M-2796 (similar to M-2795 except with a porcelain base), and M-2785.

|

|

| two-spouts |

The construction of the lines for the Bay Counties Power and Standard

Electric Companies were a great engineering feat. The main line consisted of

three aluminum cables 7/8 inch in diameter and weighed 2404 pounds per mile. An

August, 1901 article in "The Journal of Electricity, Power and Gas"

described the line from the "old-time" lineman's point of view. After

he had climbed as far as the telephone arm, looked up at the top of the power

arm, the lineman might have exclaimed:

"Well, I'll be switched! I wonder if they've got a cable road up there.

They've got a railroad tie for a crossarm, table legs for pins, a Chinaman's hat

for an insulator, and a full-grown street railway cable for wire. That's too

much for me!"

The M-2795 insulator was very unusual and entirely Fred Locke's design.

Fred's stated purpose of design can be found in an article written by him in the

November, 1901 issue of "The Journal of Electricity, Power and Gas". He believed that the higher voltages presented a problem with

insidious surface leakage that could not be stopped with longer leakage paths

provided by a multiple of petticoats. The insulator should, he thought, not be

designed with petticoats to lengthen the leakage path, but rather it should be

designed with a large arcing distance from conductor cable to pin. He stated his

best designs were the new "Victor" insulators where "the top is

extended laterally, or in an umbrella shape, and the center is extended down

around the support, also preventing arcing to the pin. All other surface is cut

out."

This design proved to be flawed and resulted in numerous problems,

particularly in areas of salt fog. One account describes problems with

mysterious grass fires along the Bay Counties line. It was discovered that the

insulators were heating up from the surface leakage to such an extent that the

sulfur cement was melting, catching on fire, and dropping to the ground igniting

the grass around the pole. The insulators proved to be of marginal service as

long as conditions were dry, and they were quickly replaced in salt fog areas

with larger insulators. In 1904, the line was completely rebuilt with M-3725 and

M-4325 made by Locke.

An interesting description of M-2795 can be found in I the August, 1901 issue

of "The Journal of Electricity, Power and Gas":

"Without tiring you with the details of the development of the insulator

that the Standard Electric company is using, I will state briefly that at the

time we adopted it there was nothing on the market that would anywhere near meet

our requirements, hence it was not until after many months of cut and try

methods had passed before we obtained an insulator that would stand the exacting

test to which it would be subjected. (The figure below] shows the Standard

insulator in section and perspective. It is what is called a two-part insulator,

the upper part being of porcelain and the lower part of glass.

There are several reasons why a combination insulator was decided upon.

First, the dielectric strength of the glass is greater than an equal thickness

of porcelain, while, on the other hand, moisture clings less readily to the

porcelain. It was also found that a much cheaper insulator could be made in this

way than making it either wholly of glass or of porcelain. As a matter of

fact, the insulator as designed could not be made of glass in one piece. The two

parts of the insulator are cemented together with a cement composed of sulfur

and sharp sand in about equal parts. After being cemented together, every

insulator is subjected to a test of 120,000 volts for period of five minutes, and if any insulator shows sign of weakness it is

rejected.

On the base of the pin is used a porcelain sleeve 5 inches long, which

rests upon the crossarm and projects up beneath the glass petticoat. The object

of this porcelain sleeve is to protect the pin in the event of an arc tending to

strike from the eave on the insulator to the base of the pin. It also protects

the pin from weathering."

The most common eave and spout insulator is M-2795, then M-2796, M-2785 and M-2335 being the rarest. Only two M-2335 are known. There is a report of 1 or 2

others that I have been trying to verify. Another one exists with a glass base,

but the crown has been cut off. One more exists that is all white, but it has

not made it into collector's hands.

All white M-2335. |

The only known M-2795 with white porcelain

top. |

There are perhaps 20 M-2785's, maybe more. These are very

hard to find available. It seems that they stay in collections for a long time.

M-2796 is closely related to M-2795 in that they used the same top. All of these

that I have seen were recently (past 10-20 years) cemented with Portland cement.

M-2795 was not originally cemented with Portland cement, but rather with sulfur,

and I suspect that M-2796 was originally cemented with sulfur as well. The great

majority of M-2795's were used on the Bay Counties and Standard Electric lines.

The great number of failures on those lines and the newly developed three-part

styles marked the rapid death (by 1902) of this eave and spout design. The flat

top was an efficient collector of dirt, the bottom skirt was easily wetted in a

rain, and the spout was of no benefit. The leakage path was too short for 40,000 volt service in all but very dry environs. It was a failed design

from the beginning.

I suspect that most of the M-2796's are really tops from the

Bay Counties and Standard Electric lines since these were so readily available

back in the late 1960's when most were found laying around separated from their

broken glass bases. The porcelain bases evidently surfaced from other lines,

but probably few whole M-2796's were found as evidenced by no specimens have

been reported with the original cement. Maybe the ground was rocky, insulators

dropped naturally top first, or poles fell over breaking the tops first. I have

seen porcelain skirts available, so it is easy to put these with available

tops of M-2795's. My first M-2796 was purchased in two pieces and later

cemented.

There is a variety of markings to be found on the eave and spout

insulators. M-2785 is only found with Fred Locke marking #6-1. M-2796 is found

with marking #4-1, but other markings as may be found on M-2795 surely exist.

Markings on M-2795 are: #1-5, #4-1, $4-2, and #6-2. Each of the two specimens of

M-2335 have different markings: #4-1 and #4-3. The earliest manufacturing date

recorded for the eave and spout insulators is "NOV 24 1900" and the

latest date that I have seen is "NOV 29 1901". Most specimens do have

a manufacturing date except for those with the #1-5 marking. The only white

M-2795 is dated "DEC 7 1900" just two days later than a tan one with

the same marking (#4-1).

Values of M-2796's are probably about equal to M-2795's

with the exception that most collectors seem to prefer the glass bottom. Glass

collectors would buy a M-2795, but more often would pass on the M-2796. So, to a

porcelain collector the values are probably the same, but overall the value

would be less than M-2795. I would guess a value of $125-150 for a good one with

the higher value for one with a pretty glaze and original sulfur cement. Mint

specimens do not exist since the thin, outside edge under the porcelain skirt,

and the spout are very brittle. All of these spouted styles are some of my

favorites particularly M-2795 and M-2335.

The value of M-2785 is probably

$150-175. Value for M-2335 is probably in the range of $300-400. Rarity in

porcelain does not necessarily command great values as does rarity in glass. Few

collectors, too, are aware of the rarity available in porcelain. If you are

interested in putting together a fine collection of uncommon to rare insulators

for a bargain price, porcelain insulators are the hidden opportunity. But, do

not wait too long. Many are becoming interested in porcelain since glass

prices so high.

Large Image (115 Kb)

Large Image (123 Kb)

|